How to Distinguish Between ACSR (Aluminum Conductor Steel Reinforced) and AAAC (All-Aluminum Alloy Conductor) / AAC (All-Aluminum Conductor)

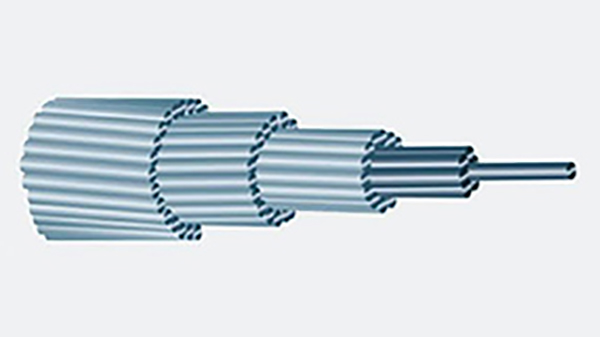

Both ACSR (Aluminum Conductor Steel Reinforced) and aluminum conductors (AAC/AAAC) are uninsulated wires, commonly known as "bare wires". People unfamiliar with the cable industry may find it difficult to distinguish between ACSR and aluminum conductors, as they both appear to be aluminum wires in terms of external appearance. So how can we distinguish between ACSR and aluminum conductors?

I. Distinction by Cross-Section Color

If the cross-section clearly shows that one or more conductors in the center have a darker color than the aluminum wires in the outer layer, it is ACSR. In contrast, the entire cross-section of an aluminum conductor has a uniform color.

II. Distinction by Wire Hardness

Due to the presence of steel wires inside, ACSR is much harder overall than aluminum conductors. A simple way to distinguish them is by holding the wire with your hand: aluminum conductors feel softer to the touch.

III. Distinction by Conductor Weight

ACSR contains steel wires inside, and as is commonly known, steel is heavier than aluminum. Therefore, you can also distinguish the two by weighing them.

IV. Distinction by Model Designation

ACSR is abbreviated as "LGJ" in Chinese standards. It is formed by stranding aluminum wires and steel wires, and is mainly used for overhead transmission lines. The inner part of ACSR is a steel "core", and the outer part is aluminum wires stranded around the steel core. The steel core mainly serves to enhance strength, while the aluminum wires are primarily responsible for transmitting electrical energy. Both ACSR and aluminum conductors belong to bare wires and are basically similar in application, but they have different representation methods in terms of model specifications.

The model designation for ordinary aluminum conductors (AAC) is "LJ" in Chinese standards, which also fall into the category of bare wires. Currently, China generally uses aluminum-clad steel stranded conductors (LGJ, i.e., ACSR) as transmission conductors. The steel core mainly functions to increase strength, and the aluminum wires are mainly used for transmitting electrical energy. The cross-sectional area of the conductor varies depending on the voltage level. For example, conductors used in 500kV transmission lines in China are generally of the type LGJ-400/35. Here, "L" stands for aluminum (lǚ in Chinese), "G" for steel core (gāngxīn in Chinese), "J" for stranded conductor (jiǎoxiàn in Chinese), 400 represents the cross-sectional area of the aluminum part (400 square millimeters), and 35 represents the cross-sectional area of the steel core (35 square millimeters).

V. Main Applications

ACSR is a reinforced conductor consisting of a single layer or multiple layers of aluminum strands stranded around a galvanized steel core. It is mainly used in the power and transmission line industry. ACSR has the characteristics of simple structure, easy erection and maintenance, low line cost, large transmission capacity, suitability for laying across special geographical conditions such as rivers and valleys, good electrical conductivity, sufficient mechanical strength, high tensile strength, and the ability to increase the distance between towers. Therefore, it is widely used in overhead power transmission and distribution lines of various voltage levels.

Generally, for high-voltage transmission wires, due to the limited path available, it is not feasible to erect multiple lines along a single path. Therefore, a solution has been adopted where multiple conductors are hung on a single path and a set of towers, meaning one line is equivalent to multiple lines erected. For example, in China, most 500kV transmission lines adopt the method of hanging four conductors, which is called "same-tower double-circuit" or "same-tower multiple-circuit" erection. This is the main reason why some towers use both "LJ" (aluminum conductors) and "LGJ" (ACSR) conductors.